voxeljet @ GIFA 2023

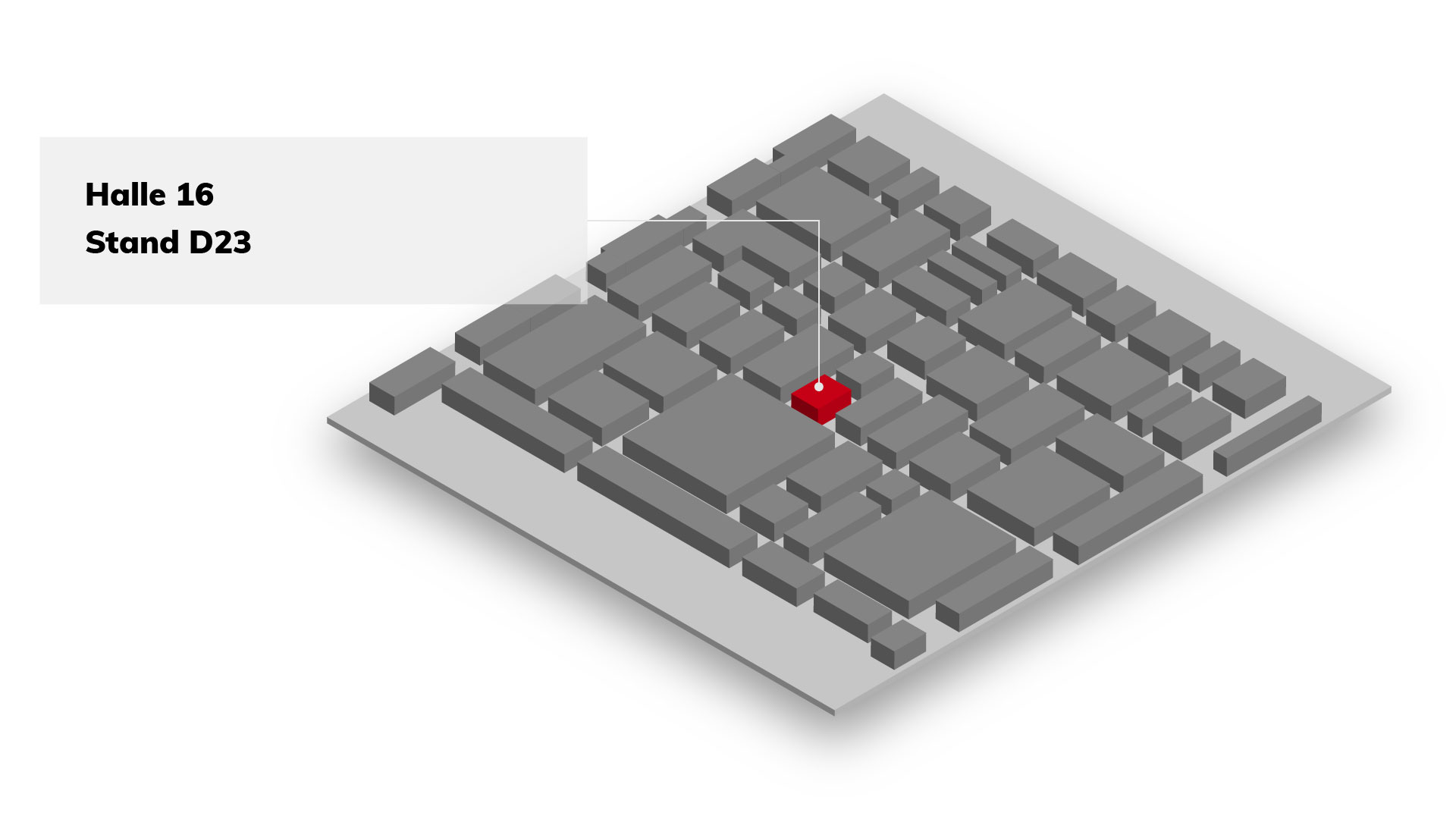

From June 12th to 16th, 2023, the world's most prestigious trade fair for foundry technology will take place in Düsseldorf, Germany. Visit us at booth D23 in hall 16 to learn more about our latest developments, innovations and 3D printing solutions for metal casting applications.

From fully automated additive core manufacturing at the BMW Group Plant in Landshut, Germany and improved inorganic process technologies to innovative product developments and lightweight design projects. Once again, we have plenty of highlights in store for you.

Take the opportunity to make an appointment with our team of experts right here.

See you soon in Düsseldorf, we are looking forward to your visit!

We make additive series production a reality

Again, we have plenty planned and will be diving deeper into the world of additive series manufacturing. You can look forward to:

- Serial additive core manufacturing at the BMW Group Plant Landshut, Germany,

- Inspiring case studies of 3D printing in sand and investment casting

- State-of-the-art equipment, sustainable material sets and technologies

Secure an appointment here with our experts at booth D23 in hall 16.

We look forward to seeing you!

Get your appointment

Inorganics in 3D printing

Get to know our new, inorganic IOB (Inorganic Binding) technology. Emission-friendly casting for prototypes and series production.

A versatile technology

3D printing is pushing the boundaries of conventional processes. Lightweight design is just one of many advantages. Discover also our furan and phenolic material sets.

Unlimited possibilities

3D printing gives free rein to creativity. Even complex parts can be produced effortlessly. Now everything that is constructively conceivable can be printed.

Our highlights

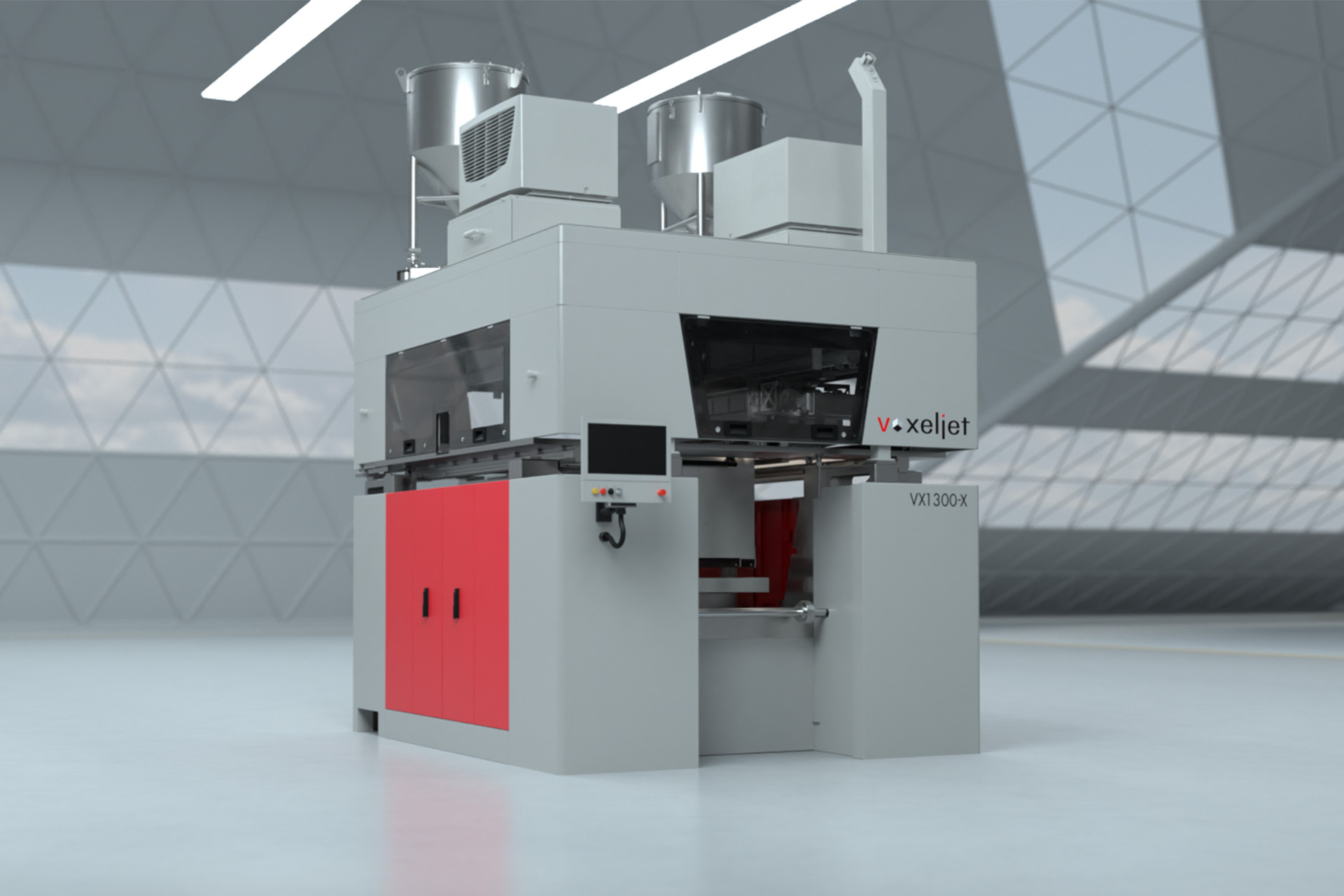

3D printer VX1300 X

The unique solution for additive series production of highly complex sand cores for metal casting - both inorganic and organic processes.

Easy complexity

What does it take to efficiently manufacture molds and cores using additive manufacturing? Let yourself be inspired by examples from electromobility.

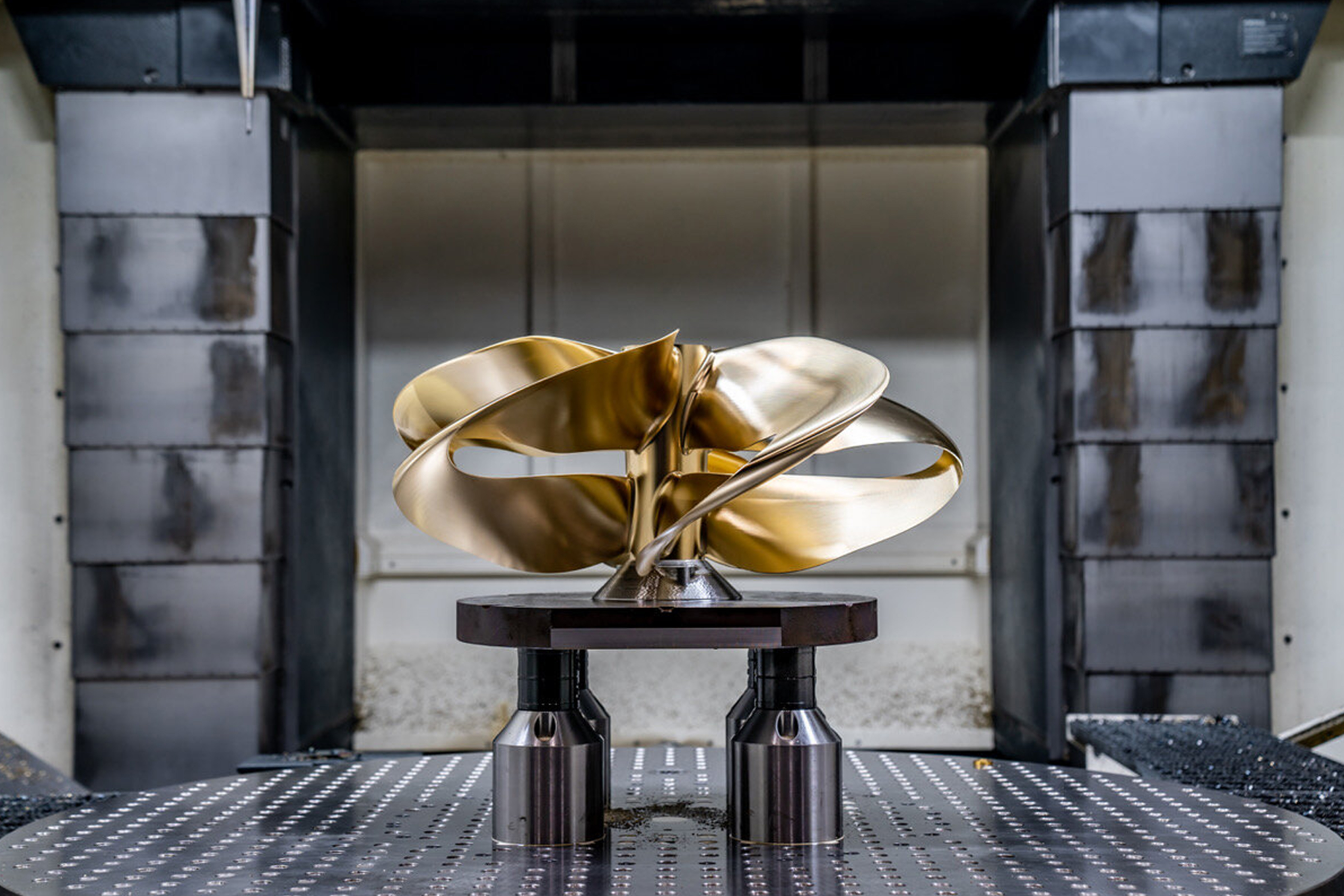

Future prop

Faster, better, more efficient. Find out from us how this propeller is revolutionizing the world of marine propulsion.

Industrialization of Core Printing

At the last GIFA we presented the ICP (Industrialization of Core Printing) project, in cooperation with Loramendi. This year, we are especially proud to say that the first additive series production line for 3D printed water jacket cores is in full operation at the BMW Group Plant foundry in Landshut, Germany. Part of this unique production cell is our VX1300 X. It exploits the full potential in interaction with integrated automation processes, unpacking and finishing processes. We are aware that every production environment is special and requires a specific automation concept tailored to the industry.

In order to provide you with the best possible solution for your production, we have joined forces with Loramendi to offer you the optimal finishing and automation tools tailored to your processes with a high level of expertise. A cooperation of the best - for the sustainable optimization of your production.

„Loramendi has built equipment for the foundry industry for more than 45 years and nowadays enjoys world-wide prestige. We are recognized as a builder of heavy duty, reliable machinery and solutions specifically designed for the unique challenges of the foundry industry” stated Joseba Goitia, General Manager of Loramendi. “We are really excited about starting this new journey that will completely transform the landscape of the foundry industry and set new standards for core making.“

Joseba Goitia, General Manager

Loramendi

Our VX1300 X

The VX1300 X 3D printer is our unique solution for the additive series production of highly complex sand cores for metal casting. Productivity is just one of the many features of this printer. Designed to be intelligent and low-maintenance, the VX1300 X can be integrated into existing Industry 4.0 networked production environments. The tool-free production of highly complex sand casting cores maximizes the design freedom of designers while minimizing tooling costs.You'll find us here

Secure an appointment here and visit us at booth D23 in hall 16.